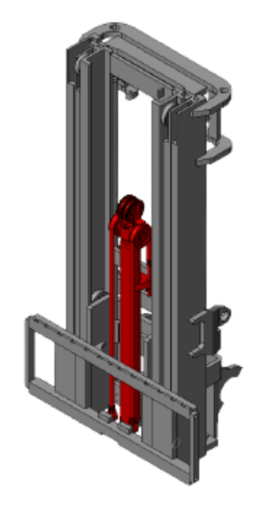

MAST & CARRIAGE REPAIRS

MAST & CARRIAGE REPAIRS

MAST CROSS-MEMBER AND CARIAGE CRACK REPAIRS:

Forklift’s mast cross-member and carriage crack repairs are crucial to ensure forklifts’ safe and efficient operation. When cracks or damage occur, welding and metal fabrication techniques can be used to repair them. Heavy equipment welding repair is a specialized skill, and working with reputable welding and fabrication companies with experience in this area is important. Forklifts Welding and fabrication services can provide the necessary repairs to keep forklifts in good working order, minimizing downtime and preventing safety hazards. Inspections and maintenance can help prevent damage and catch problems early.

MAST/CARRIAGE STUB SHAFT REPAIRS:

Forklifts are commonly used in industrial settings to move heavy loads, and their mast/carriage stub shafts are critical components that support the lifting mechanism. When these shafts become damaged or worn, on-site welding services can be used to repair them. With mobile welding services, forklifts don’t need to be transported to a repair shop which will save you time and money. With the right expertise and equipment, a skilled welder can repair the mast/carriage stub shafts to restore the forklift to safe and reliable operation.

MAST TRUNNION REPAIRS: Forklift’s mast trunnion repairs involve fixing the forklift part that supports the mast and allows it to pivot. This repair may include replacing worn or damaged parts, welding, or realigning the trunnion to ensure the safe and effective operation of the forklift.

INFORMATION REQUEST X